The Society of Automotive Engineers (SAE) at California State University, Long Beach, is elated to announce the arrival of AnkerMake as an official sponsor of our esteemed organization. As an automotive engineering organization, we constantly seek novel and inventive means of enhancing our manufacturing processes. Accordingly, we sought out AnkerMake.

The utilization of 3D printing technology in the automotive industry has completely transformed manufacturing and design processes. With AnkerMake's cutting-edge M5 3D printer, SAE is now empowered to leverage this technology to produce parts and components with unparalleled precision and efficiency

AnkerMake M5's User-Friendliness Defies Expectations

The AnkerMake M5 3D printer is truly a game-changer, particularly in terms of its accessibility and user-friendliness. 3D printers do not have the best reputation when it comes to ease of use and quick set up. However, with a mere three-step set-up process, the printer can be fully operational within 15 minutes.

AnkerMake has made it easy for both new and old users of 3D printers to quickly begin 3D printing, especially through their easy-to-follow instructions and videos. The printer's peerless features, such as:

The 7x7 auto-leveling system which allows users to simply press the auto-level button on the screen and leave it alone for 10 minutes.

The included PEI soft magnetic printing bed allows for prints to easily be removed, no need for a glue stick!

AnkerMake has thoughtfully included an auto-resume function following power outages, and printing notifications, conspire to make the printing process worry-free.

User interfaces have never been a strong point in the 3D printing industry, but AnkerMake has made it easy to navigate through the M5’s settings with a large touchscreen and clearly labeled settings. It’s been a real pleasure using the M5’s interface and features especially considering AnkerMake’s constant updates to users and addition of features.

A built-in camera allows users to remotely monitor print jobs for issues, which helps reduce wasted time and valuable printing materials. And time-lapse videos are automatically generated after the printing job is complete.

Two of our favorite features thus far are the addition of the step counter, showing how many steps have taken place and the total number of steps as well as the inclusion of the camera itself! The step counter is a great addition to the M5 given that it allows for users to pause the printer at the right place should another 3D part need to be added. This is one way to create complicated 3D printed parts, and the step counter aids in this process. The camera has allowed us as students to monitor prints from our phones to ensure there is interference or spaghetti-like strings.

Revolutionize Your Work with M5's Lightning-Fast Printing Speed and Pinpoint Accuracy

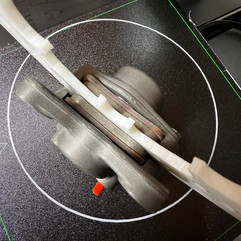

AnkerMake M5 impresses with its remarkable combination of printing speed and precision, delivering an exceptional 3D printing experience. The M5 boasts amazing extruder acceleration of 2,500 mm/s² and print speed of 250 mm/s. These speeds are also adjustable, making it easy to choose between detailed and smooth final prints, or fast and prototype prints! The M5's remarkable capabilities have bestowed SAE with the ability to print an extensive variety of components and parts, such as brake rotors and suspension knuckles, which can be utilized in the automotive manufacturing industry for prototyping and allow for print times to be reduced by 70%.

In addition, SAE can and plans to fabricate jigs and fixtures that aid in CNC manufacturing. A large part of SAE’s Baja project consists of designing and building parts from scratch. One of the most important parts of our project is the chassis component. Though our team is filled with enthusiastic and hardworking members, there is little to no experience in the fabrication of such components. The chassis presents itself as a challenge given our limitations in tooling, machine shop time, and welding knowledge. It is crucial that when welding precut and bent tubes together that we attempt to keep tubes inline and in the exact position we designed them to be such that alignment is maintained, and tolerances are kept to a minimum. Our team has concluded that the best way to go about this is through the creation of custom jigs aiding in the welding process. Thanks to CAD software and the M5, we can design, and 3D print various custom PLA+ prints that perfectly fix our issues and reduce failure in alignment. Just recently we received donations of tooling aiding our manufacturing process in our shop. There are various organization pieces that can be bought for toolboxes, but sometimes organization solutions fail to exist for some tooling or are simply too expensive. The M5 yet again makes this issue solvable. The M5 has no issues repeatedly printing socket holders with great quality at high speeds with high acceleration. These 3D printed parts are significantly more cost-effective than traditional manufacturing techniques and can be produced with unparalleled precision and efficiency.

(Left to right: First layer on the M5; Fitment test of one-piece of a printed brake rotor in a brake caliper; Fitment of two-piece printed caliper in brake caliper; Print of front suspension knuckle and printed jig to be used in a CNC mill)

AnkerMake Keeps Optimizing Based on User Feedback

AnkerMake initially released their slicer software, still in beta, while actively seeking feedback to enhance the slicer’s functionality. The inclusion of an AI-powered camera for detecting errors is a sophisticated feature that was initially exclusive to AnkerMake’s slicer. AnkerMake constantly listens to users through mediums such the official AnkerMake Discord server where users share concerns and what they feel may have room for improvement. There have been many who adapted profiles to be used in slicers such as Cura and Prusa. AnkerMake understands the importance of appeasing to users and listening to them. Thanks to many experienced users in the 3D industry who provided input, AnkerMake has made a transition to have their slicer be based on PrusaSlicer, improving the experience for all users, yet still maintaining a user-friendly interface that can be accessed by new M5 users.

AnkerMake Inspires Limitless Innovation

AnkerMake’s M5 represents a significant milestone in the field of 3D printing technology, particularly in terms of its exceptional print speed and quality. Moreover, it is a noteworthy feat of engineering, given its ease-of-use and superior software design, which is accessible even to novice users. AnkerMake's M5's superlative features, including the remote monitoring and error detection enabled by the in-built camera, make the printing process stress-free and straightforward.

SAE at CSU Long Beach is deeply grateful to AnkerMake for sponsoring our organization, and we encourage all those who are interested in 3D printing technology to explore the M5 on Amazon or AnkerMake's official website, where it is available for an MSRP of $799, and for a limited time, you can receive $120 off your order! By partnering with AnkerMake, individuals, students, hobbyists, professionals, and everyone else can learn and enjoy seamless high-speed, high-quality printing experiences!

Additional Information and Specs:

5x industry average print speed (250 mm/s in standard print mode)

2,500 mm/s² in accelerated print mode

Can reduce average print time by up to 70%

Print error detection with auto shut-off

Integrated HD camera with remote viewing

Supports Wi-Fi and USB connectivity

Easy filament loading and extraction with heat assist

Magnetic base for easy removal and cleaning

Weight: 12.4 kg / 27.3 lbs

Measurement: 502 x 438 x 470 mm / 19.76 x 17.24 x 18.50 inches

Comentários